Tools ranking 2020 recommended by selected Cominix salespeople

Recommended tools ranking based on experiences.

We asked 57 salespeople in Cominix to select the recommended tools from the 1st to the 5th place "based on their own sales experiences".

Rules:

1. Recommended tools based on own sales experiences

2. Explain the specific reason for recommending from performance or the price

3. The product which Cominix is handling

4. Only the 1st place (or 2nd place) selecting is available because the concept is "the tools really recommended"

How to give points:

5 points for the 1st place, 4 points for the 2nd place, 3 points for the 3rd placem 2 points for the 4th place, and 1 point for the 5th place.

The tools with the most points will be shown in order from the 10th place.

* The comments in this article is based on Cominix salespeople experiences.

This is not reflecting actual test at Cominix Technical Center.

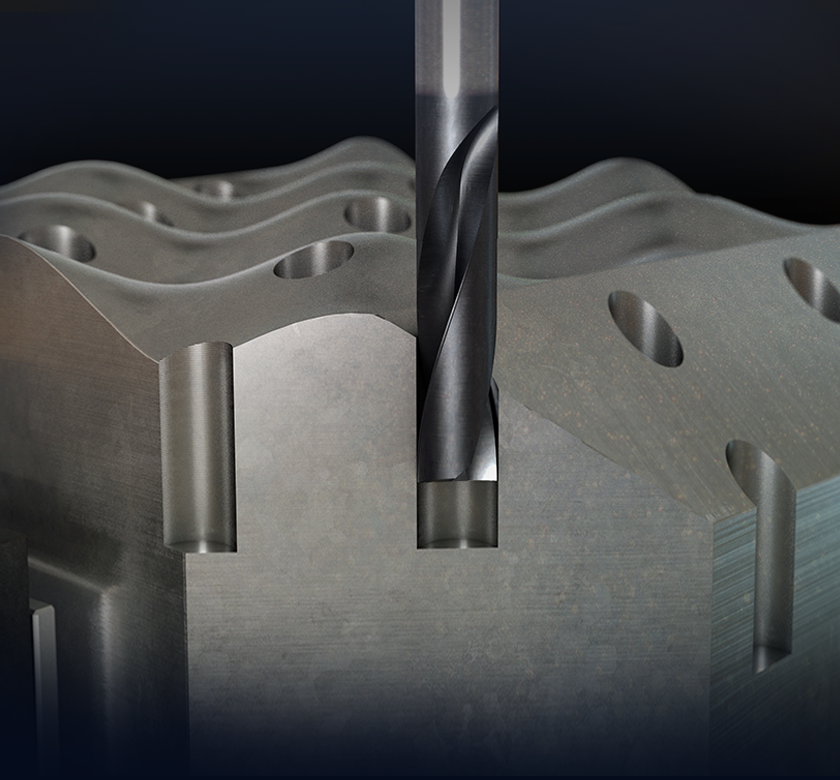

The 10th place

YG-1 flat drill

DPP447, DPP450

≪Comments from Cominix salespeople≫

・ Recommended for countermeasure of cloudiness and chip control with alloy steels and carbon steels which are sticky material.

・ Improved cutting condition to 1.2 times and better chip evacuation and the tool life than current tool.

・ Excellent sharpness and a very good YG product not only in terms of cost but also in terms of performance.

Past article of this product.

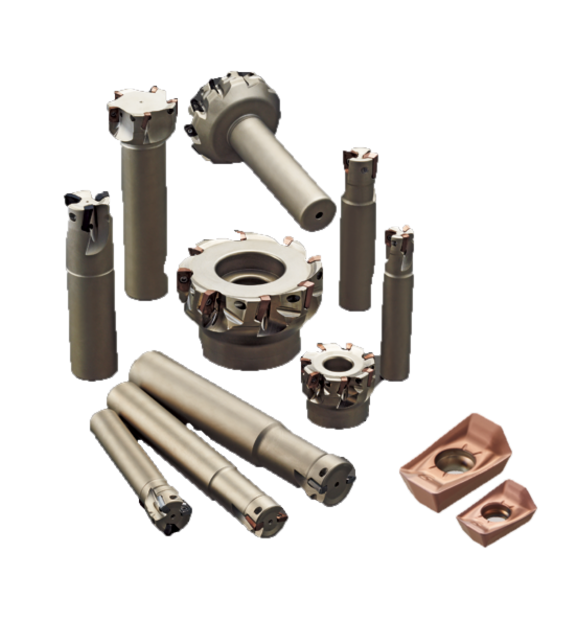

The 9th place

Walter BLAXX, Corner cutter (milling cutter)

≪Comments from Cominix salespeople≫

・ From many years of experience, cutter body has the most durable compared to all manufacturers.

・ The wall surface is outstandingly good, and the surface accuracy is also good.

・ In my customer's case, roughing and finishing were originally separated process, but this tool has enough rigidity and finishing accuracy enough to meet requirements in one operation.

The 8th place

TANOI MFG. Zero Chip Taps

≪Comments from Cominix salespeople≫

・ Reduce chip remain ratio 30% to 0%. Extend the tool life 2 times to 5 times. No screw defects or defective outflow.

・ 2 times longer tool life compared to conventional center through

・ Won the Japanese Minister of Economy, Trade and Industry Award

Past article of this product.

The 7th place

New century endmill 4NV series

≪Comments from Cominix salespeople≫

・ Excellent performance and cost performance with wide lineup of length of cutting.

・ It is common to change from solid endmills to indexable endmills, but New century is cost-effective enough to change from indexable type to solid even with a large diameter.

・ Although it is an affordable anti-vibration end mill, it has good performance and is highly satisfied by most users.

Past article of this product.

The 6th place

Soneda carbide holder

MAX V POINT

≪Comments from Cominix salespeople≫

・ The material of the insert seat surface is generally made of steel even for a carbide holder. However, since MAX V uses a tungsten material, there is less damage and vibration.

・ Especially recommended for Φ10 or less which have high damage ratio.

The 5th place

YG-1 endmills for high hardened material

X5070

≪Comments from Cominix salespeople≫

・ By using nano grain as the carbide base material, it is very heavy compared to other manufacturers' products. Easily feel the difference in the rigidity of the tool itself.

・ It was possible to extend machining from 1.3 workpieces to 8 workpieces compared to Japanese end mills for high hardened material.

Past article of this product.

The 4th place

Sumitomo Corner cutters, endmills

WEZ series

≪Comments from Cominix salespeople≫

・ The insert material "ACU2500" can be used for steels, stainless steels, castings, and difficult-to-cut materials. It has excellent sharpness.

・ Excellent versatility with many variations. Possible to suggest for any machine by wide lineup of product such as shell type, and short shank type for multi-tasking machines.

・ Since the processing accuracy of the bottom surface is high, it can be proposed changing from solid type for multi-tasking machines.

The 3rd place

Walter youtube channel:Walter Tools Turning Tiger-tec Silver UD4 Grooving Gear Wheel Machning

Walter parting and grooving

SX, GX, DX series

≪Comments from Cominix salespeople≫

・ The amazing test result with parting machining was 2 times faster cutting condition and 7 times longer tool life.

・ Extremely smooth surface roughness and long tool life. Originally user used cermet, but changed due to excellent finishing surface.

・ It is a long-selling product for the past few years.

Past article for DX series.

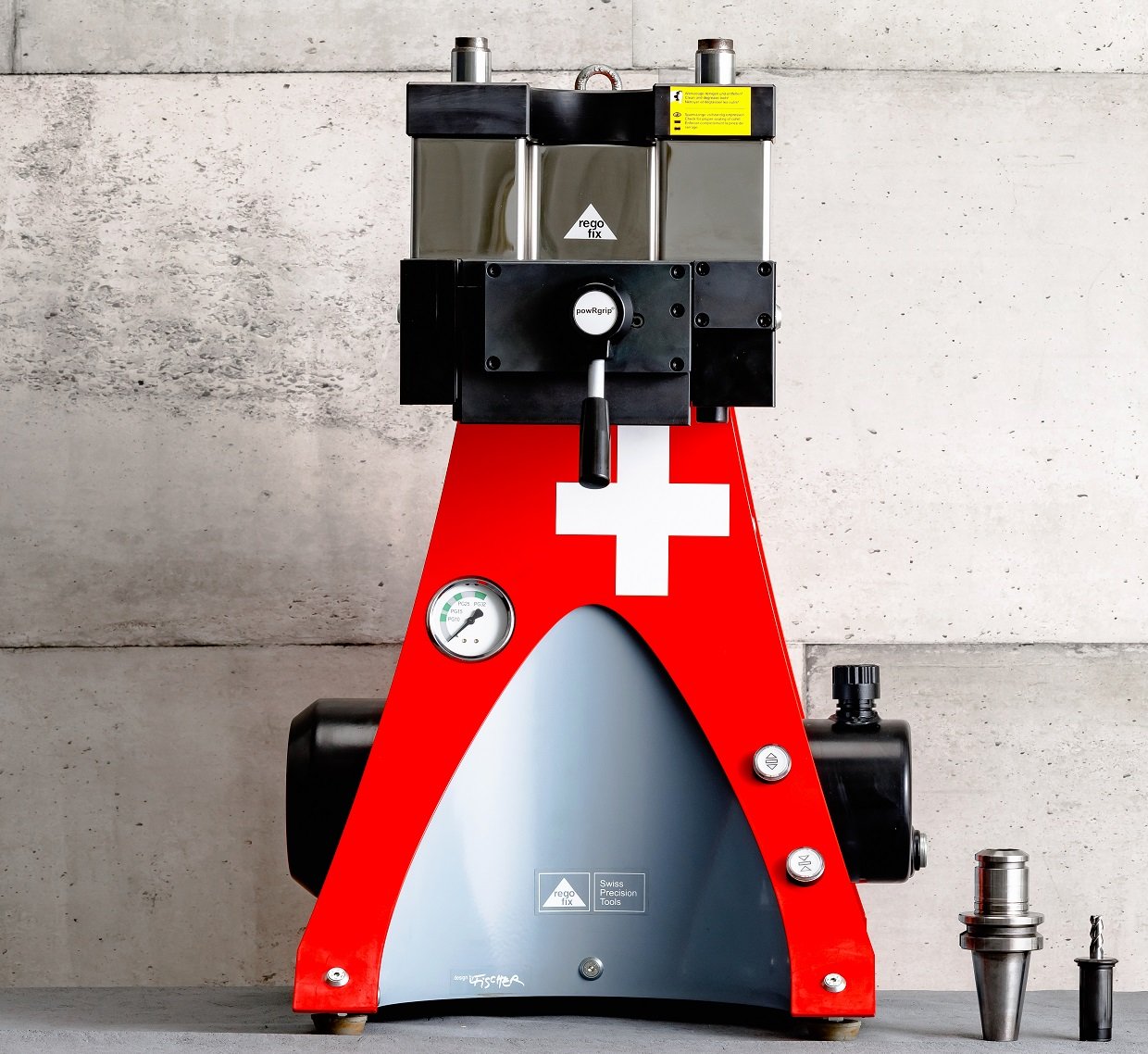

The 2nd place

REGO-FIX Pressure Clamping System with High Rigidity and Precision powRgrip

≪Comments from Cominix salespeople≫

・ It is the best product that is nothing better than this product in terms of performance (runout accuracy, clamping power, quick attachment / detachment). It is the No. 1 performance not only for tooling but also for all Cominix products.

・ Compared the machining accuracy with different holders, and it was the best result. Compared product: shrink fit, hydrochuck

・ Since the wall surface did not collapse during pocket machining and it was no longer necessary to do zero-cut machining after finishing the vertical wall.

Past article of this product.

The 1st place

Guhring High performance reamer

HR500 series

≪Comments from Cominix salespeople≫

・ Possible to propose by changing boring tools for large diameters in addition to changing reamers.

・ Significant life improvement due to feed speed (reduction in tool scraping frequency) A reamer that can be regrinding and recoated with the same diameter tolerance.

・ There is a comment from user that the current production line cannot be established without the HR500 reamer.

Editorial note

This time, Gouring HR500 reamer ranked first place while the top three tools had a good reputation and gained overwhelming popularity.Unfortunately, the tools that were not listed in the top 10 were also very close points. My favorite tool, EWS varia and YG-1 4G mills, were ranked in the top 20.

Next time, the situation may change drastically, including new products announced by each company's JIMTOF / MECT.

We would like to continue to provide recommended information that cannot be explain in the catalog, so we look forward to your continued support. (Ikeda)