Want to use a indexable end mill with a large diameter, a large number of flutes, and sharpness even with low rigidity machines?

Outline

In automatic lathes and small lathes, you may need to process using the cutting edge of the end mill for D-cut of cylindrical workpiece which corner R is specified.If you select a commercially available inexpensive solid endmill to keep costs down, due to a typical design, the cutting edge length may be longer than necessary which causes vibration, or there may be no suitable lineup of corner R for the workpiece.

Also, when considering to change a larger diameter size in order to reduce the number of passes and shorten the cycle time, special reaction is needed if it is necessary to make the shank diameter smaller than the cutting edge diameter due to machine or tooling problems. Therefore, the cost will increase significantly.

On the other hand, the indexable type has fewer flute than the solid type which is difficult to increase productivity, shorter tool life due to the lack of sharpness. There also would be concern about the frequency of replacement.

In order to solve the problem of end mill machining of automatic lathes and small lathes, we compared some characteristic tools of solid tip and indexable type.

Test conditions

In order to evaluate tools with different number of flute and diameters under the same condition as much as possible, tested under the following unified conditions.Peripheral speed: Vc=80m/min and Vc=140m/min

Feed: 0.05mm/tooth

ap=1mm x 2 passes

ae=80% of tool diameter

Tested tools

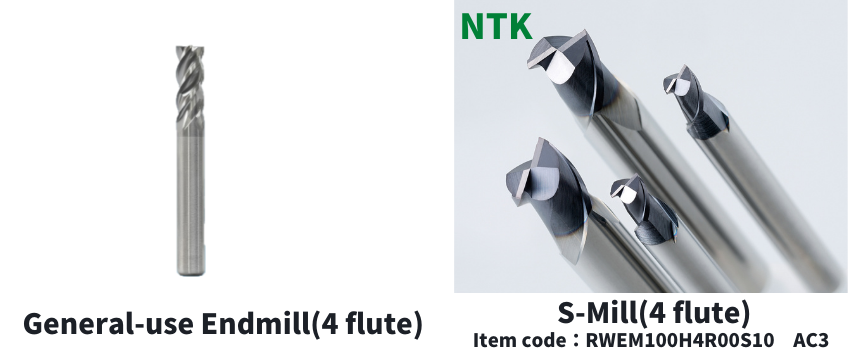

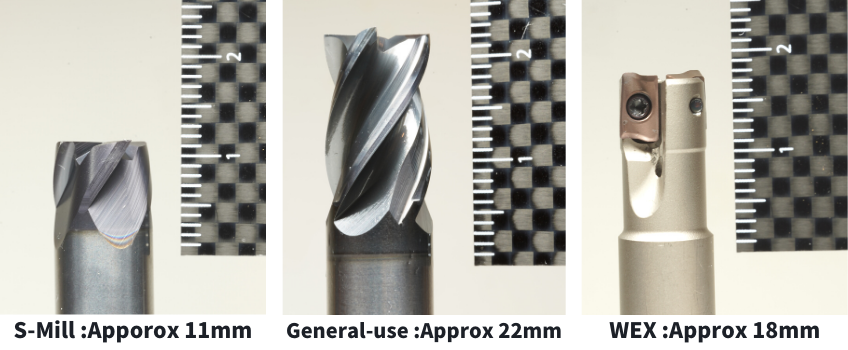

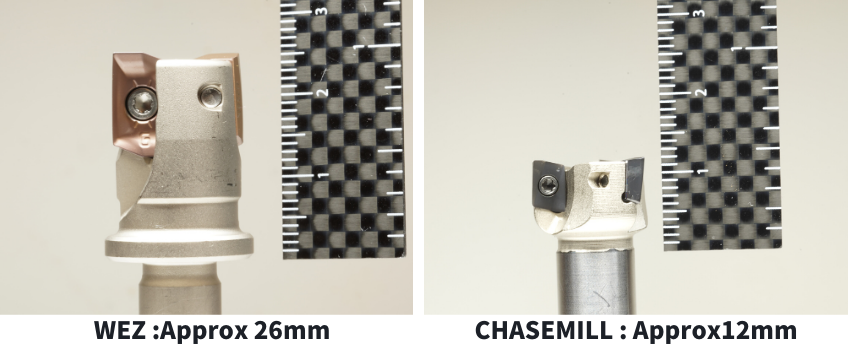

Solid endmills

Indexable endmills

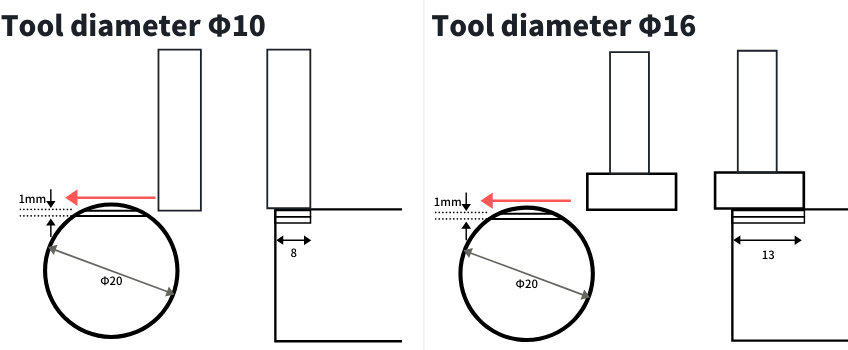

Selected maximum diameter tools of each series under the condition that the corner R is 0.2 and the shank diameter is Φ10.

-

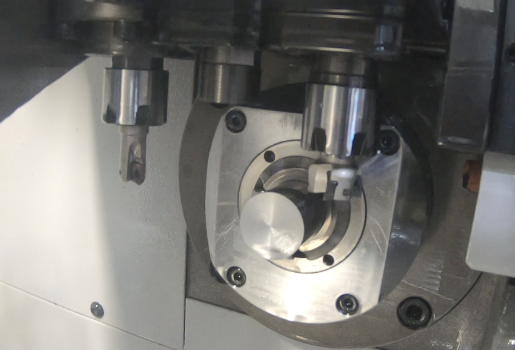

Machine

CITIZEN MACHINARY

cincom A20

Dry machining -

Workpiece condition

Size: Φ20

Workpiece material: S45C

Overhang for Φ10 endmill

Overhang for Φ16 endmill

Explanation video

You can check machining noise and visualized vibration.

D-cut Battle

Test result

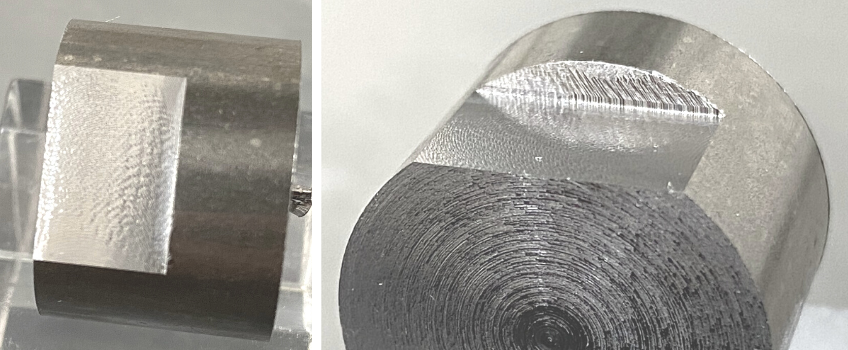

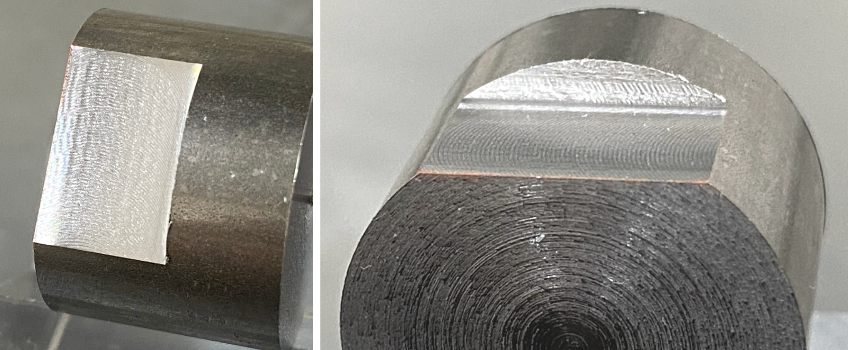

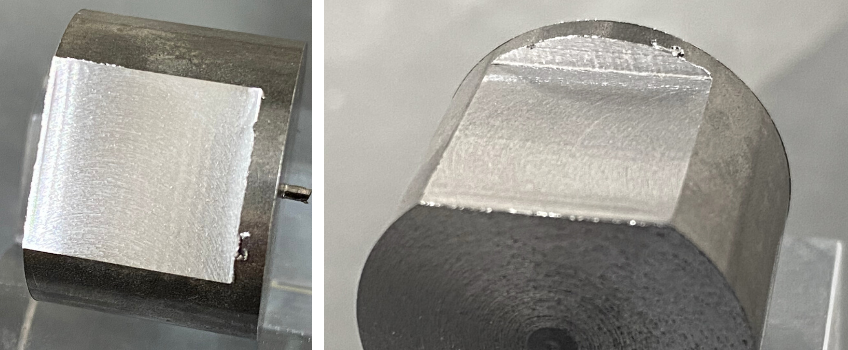

General-use solid endmill Vc=80m/min

Scale-like patterns are generated on the bottom, and stripes are strongly generated on the wall surface.There are few burrs, but unstable machining could be expected.

General-use solid endmill Vc=140m/min

Wavy patterns are generated on the bottom.

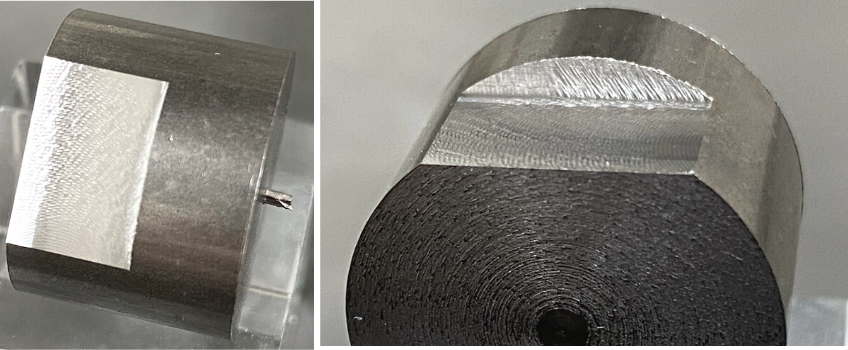

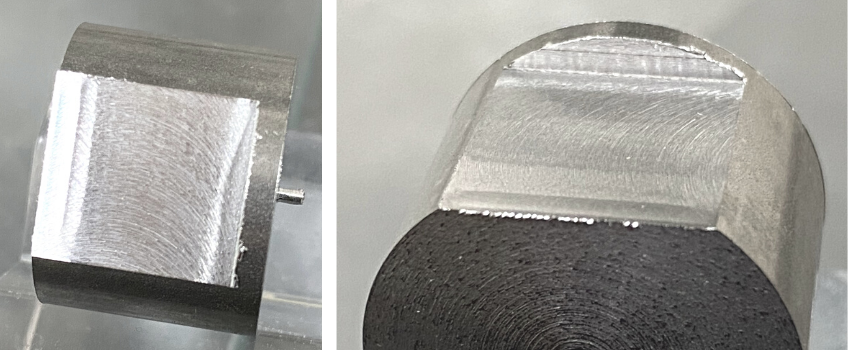

NTK S-Mill Vc=80m/min

The bottom surface is smooth. Small burrs and stripes can be seen on the wall surface, but the results are generally good.

NTK S-Mill Vc=140m/min

Scale-like patterns are generated on the bottom. Stripes are generated stronger on the wall surface compared to the condition of Vc=80m/min.

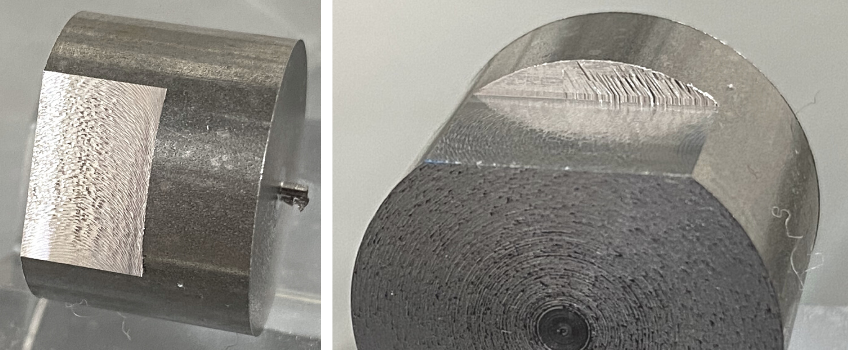

Sumitomo WEX Vc=80m/min

The bottom surface is smooth. However there are large burrs and it is strongly clouding on the wall surface. Also used an L breaker which emphasizes sharpness, but this tendency did not change.Note: Standard product of L breaker is corner R0.4 or higher.

Sumitomo WEX Vc=140m/min

Stronger clouding on the bottom and the wall surface. Burrs conditions are not improved.

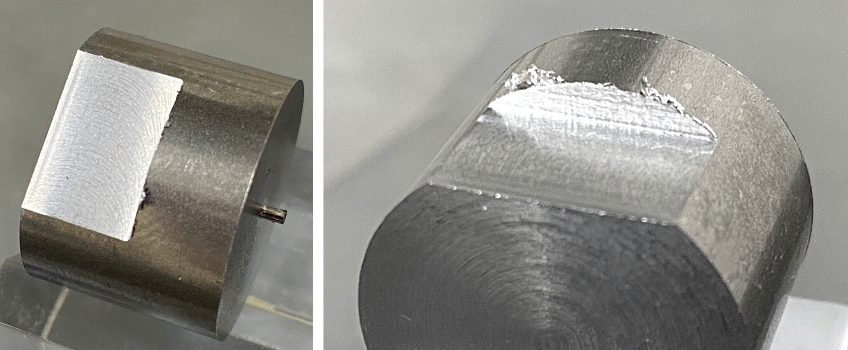

Sumitomo WEZ Vc=80m/min

Smooth surface on both the bottom and the wall. There are some burrs on the wall surface and corners when the tool leaves the workpiece.

Sumitomo WEZ Vc=140m/min

The tool mark on the bottom surface is noticeable, but there is few change by increasing peripheral speed compared to other tools.

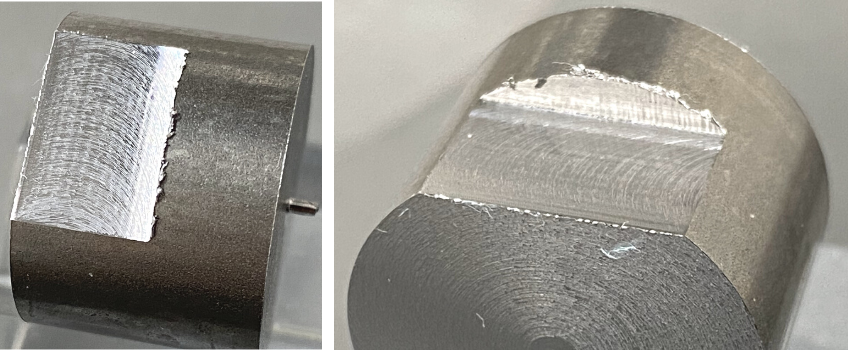

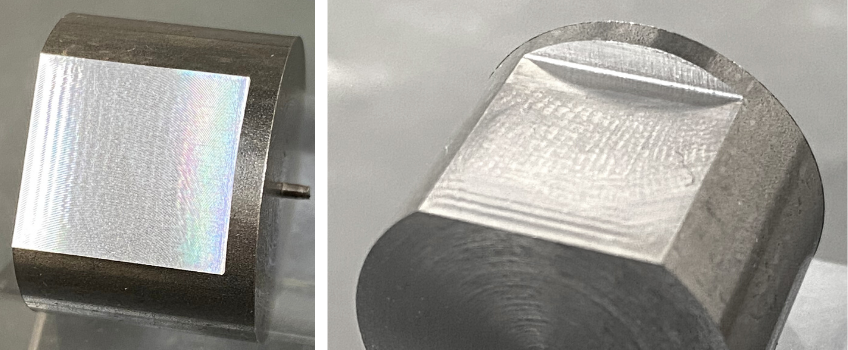

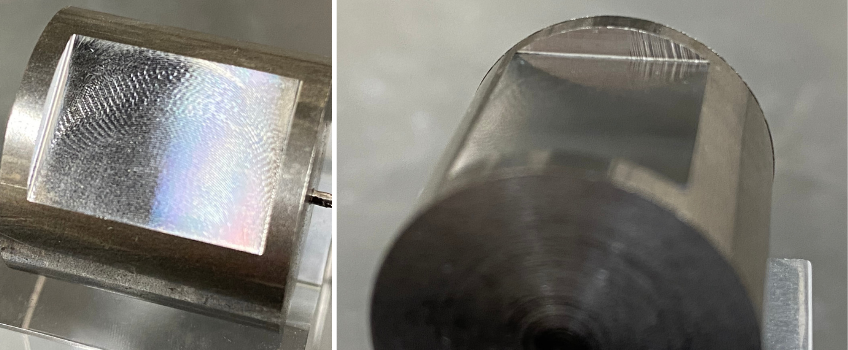

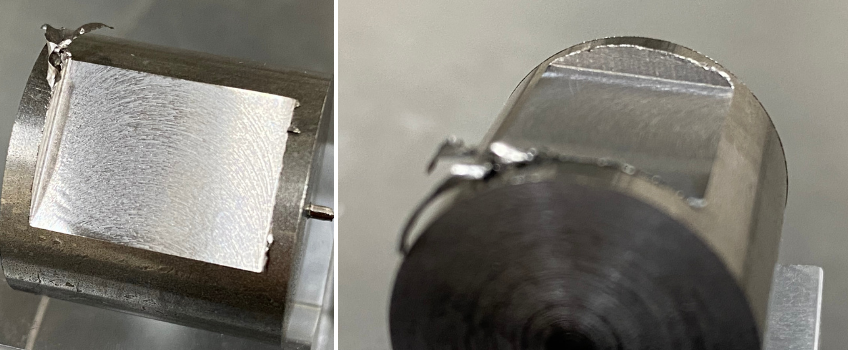

TaeguTec CHASEMILL Vc=80m/min

Both the bottom surface and the wall surface are glossy, and no burrs. It is the best test result in this time.

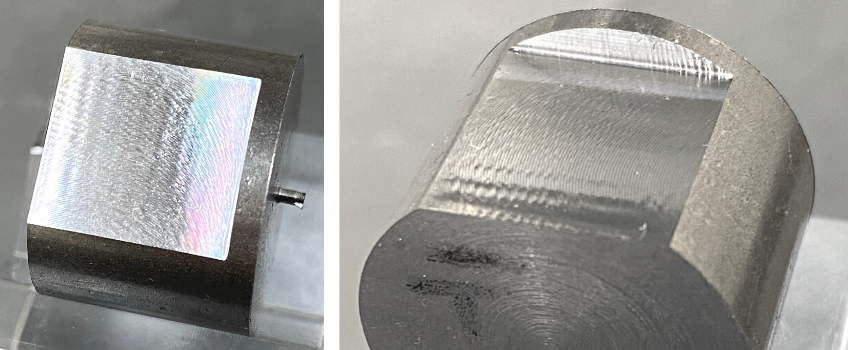

TaeguTec CHASEMILL Vc=140m/min

Bigger machining noise and the bottom surface is rougher. However, there is no burr and cloudiness.

Slotting (ae=16mm) TaeguTec CHASEMILL

Unstable machining under this condition and the bottom surface is not smooth. Since this is good sharpness, there is no burr.

Slotting (ae=16mm) Sumitomo WEZ

The bottom surface is relatively smooth because cutting force is reduced by setting the holder and the end face together. However there are large burrs.

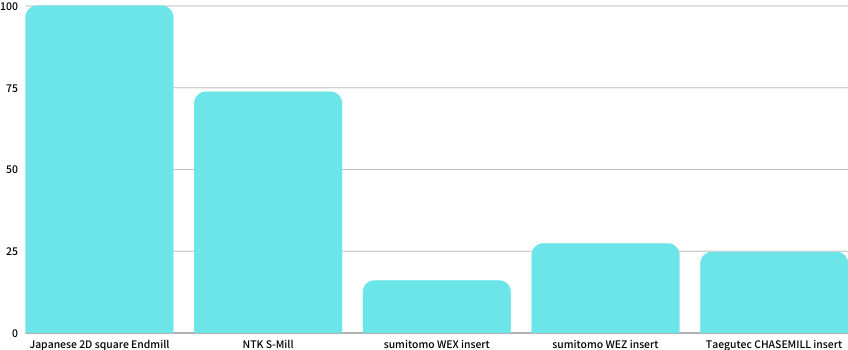

Tool cost

Price comparison : Japanese General-use endmill is taken as 100.Calculated based on the unit price per flute (1 corner).

E.G.

4 flute endmill: Unit price ÷ 4

Insert: Insert unit price ÷ 2

The insert is selected the minimum size of corner R0.2.