What's so great about high efficiency reamer?

Outline

In Cominix there are many successful cases of using high-efficiency reamers, and it has become a tool that is easy to recommend to customers.

However, there might be people who have never used it or did not know it.

Sumitomo launched the highly efficient reamer SSR as a new product in 2020.

We compared it with the popular Guhring HR500 and collected data that would be helpful.

INDEX

What is the high efficiency reamer?

It is a reamer that can achieve high rotation speed and high feed with high accuracy.

-

Recommened maximum cutting condition

Tool: Φ8 diameter reamer for general steels

Cutting condition: 240~300 mm/min with the table feed -

Recommened maximum cutting condition

Tool: Φ8 diameter reamer, Guhring HR500

Cutting condition: Max. 17,910 mm/min with the table feed

You can see that there is a big difference in the recommended cutting conditions of the catalog values between the general-purpose reamer and Guhring HR500.

In addition, it could be expected to extend the tool life significantly due to reducing the number of times the tool scratches against the workpiece by the high feed per rotation.

Why is the high efficiency machining possible?

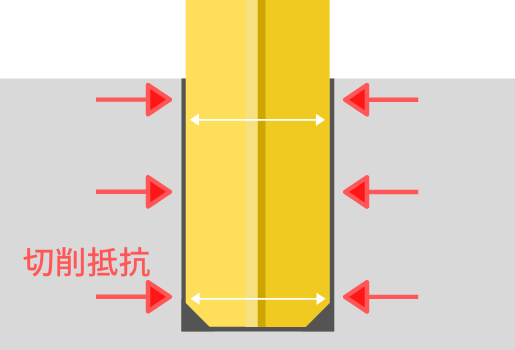

Reason 1: The difference in back taper

-

Usual general-purpose reamer: Small back taper

→ High feed is not available.

The contact area between the workpiece and the outer circumference of the tool is large by small back taper, and the cutting force area is becoming large. -

High efficiency reamer: Large back taper

→ High feed is available if the machine is rigid and accurate. The contact area between the workpiece and the outer circumference of the tool is small by relatively large back taper, and the the cutting force area is also becoming small.

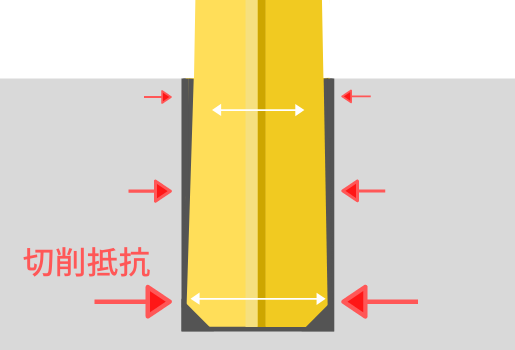

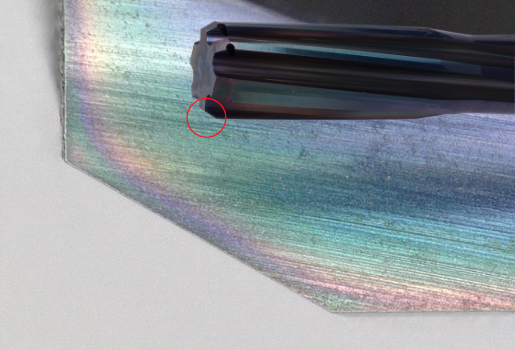

Reason 2: Higher level of surface quality compared to conventional reamers

Surface quality required to achieve high feed

Extremely high levels of surface quality are required to reduce cutting force due to high feed.

* By pursuing quality of both tool base material and coating.

(*According to Sumitomo development)

(Photo is refered from Sumitomo reamer SSR catalog)

Features of high-efficiency reamers of Guhring and Sumitomo

Then, let's check the difference between Guhring's reamer HR500 which have long been popular and Sumitomo's new reamer SSR.

① Difference in the engagement angle of blind hole type

-

The engagement angle of Guhring: 30° for through hole, 60° for blind hole

Advantage: Possible to process very close up to the bottom of the blind hole.

Disadvantage: The blind hole type has a larger impact on the cutting edge when biting compared to Sumitomo. -

The engagement angle of Sumitomo: 30° for both through hole and blind hole

Advantage: The impact on the cutting edge is reduced since it bites softly.

Disadvantage: It is not possible to process very close up to the bottom of the hole compared to Guhring in the case of a blind hole since the flute part is longer.

*The pilot hole has a 45 ° chamfering angle.

-

The engagement angle of Guhring: 60° (Total 120°)

Possible to process very close up to the bottom of the blind hole, but it bites relatively hard.

-

The engagement angle of Sumitomo: 30° (Total 60°)

Not possible to process very close up to the bottom of the blind hole, but it bites relatively soft.

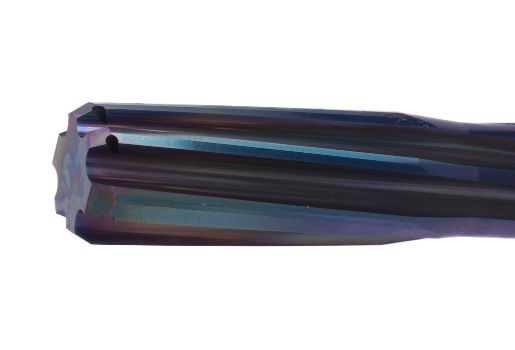

② Difference in the flute shape

-

Guhring: Straight flute

Advantage: Strong cutting edge

Disadvantage: Poor chip evacuation and shapness -

Sumitomo: Low-helix flute (right)

Advantage: Excellent chip evacuation and shapness

Disadvantage: Weak cutting edge

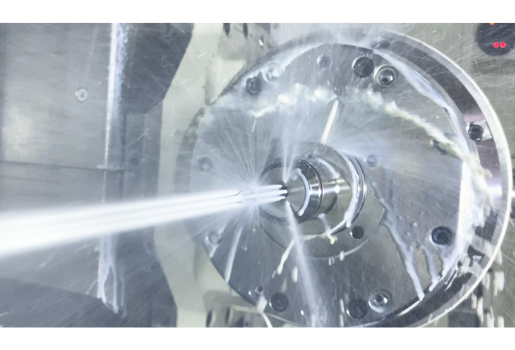

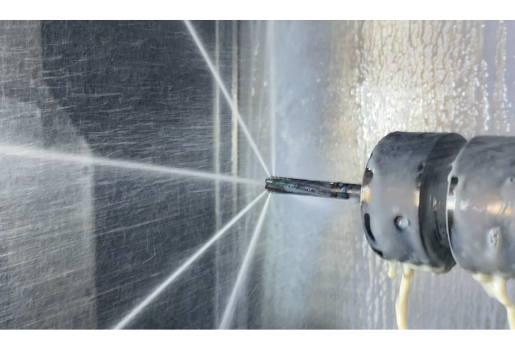

③ Difference in coolant system for through hole

-

Guhring: Shank through

-

Sumitomo: Branching around the tip area

④ Product lineup

-

Guhring: Solid and large dia. indexable types are available.

We, Cominix have plenty of stock for the vatiation.

Standard product includes for cermet material, cast iron, and aluminum. -

Sumitomo: Only solid carbide is available.

(as of Feb 2020)

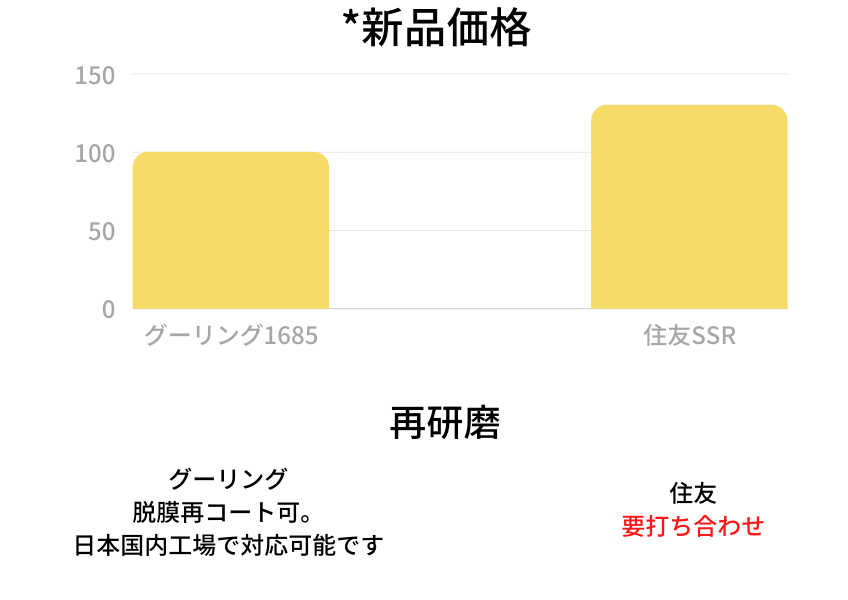

⑤The tool prices

* Price comparison gragh when HR500 is 100.

* Comparing with Φ8 coated solid carbide type.

Test report

Test overview

From the above features, it was found that Guhring is designed with an emphasis on cutting edge strength, and Sumitomo is designed with an emphasis on sharpness.

Therefore,

we considered that it would be possible to suggest"Sumitomo reamer SSR" for the low to medium rotation speed and feed range where sharpness is required, and "Guhring reamer HR500" for the high speed and high feed where cutting edge strength is required.Then conducted tests to verify.

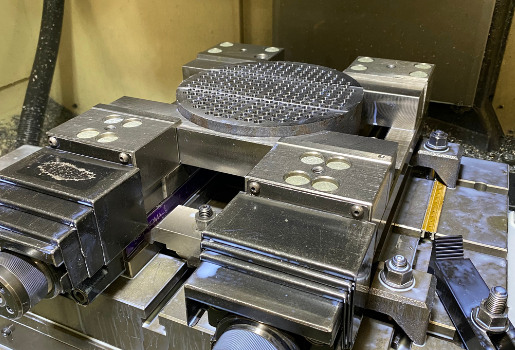

Test condition

Testing with the lower limit (Vc = 80m / min, f = 0.6mm / rev) and upper limit (Vc = 250m / min, f = 1.5mm / rev) of each catalog.

Checking what kind of difference will occur in each reamer in terms of hole accuracy, chip evacuation, and cutting edge due to differences in machining conditions.

Testing tools

Guhring: 1685 08.000 (Coolant system:Center through)

Sumitomo: SSR 08000JS (Coolant system:Center through)

-

Machine: ROBODRILL (BT30)

Coolant pressure: 2MPa, approx. 10% emulsion -

Workpiece: SCM415

20mm depth Blind hole

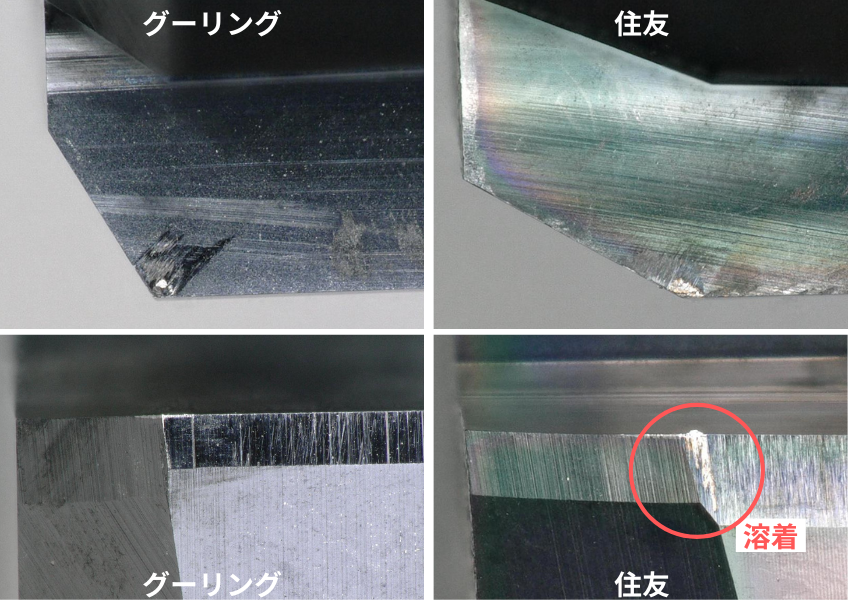

Test result

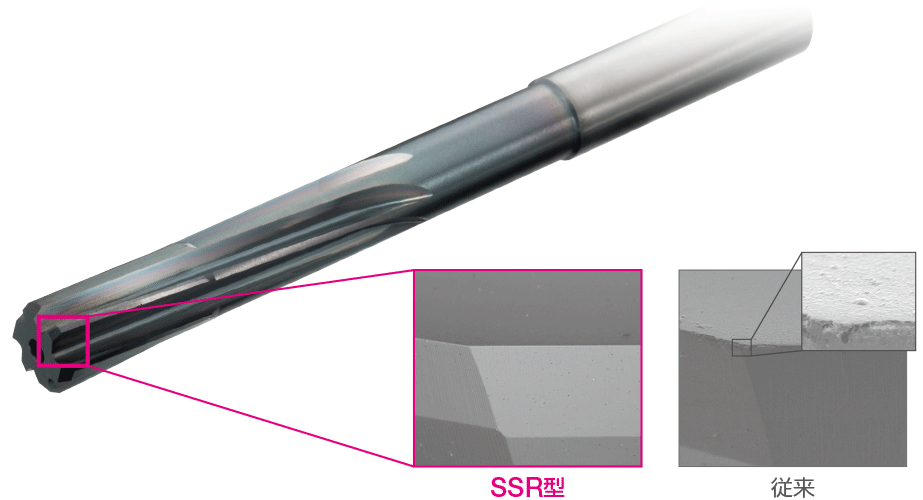

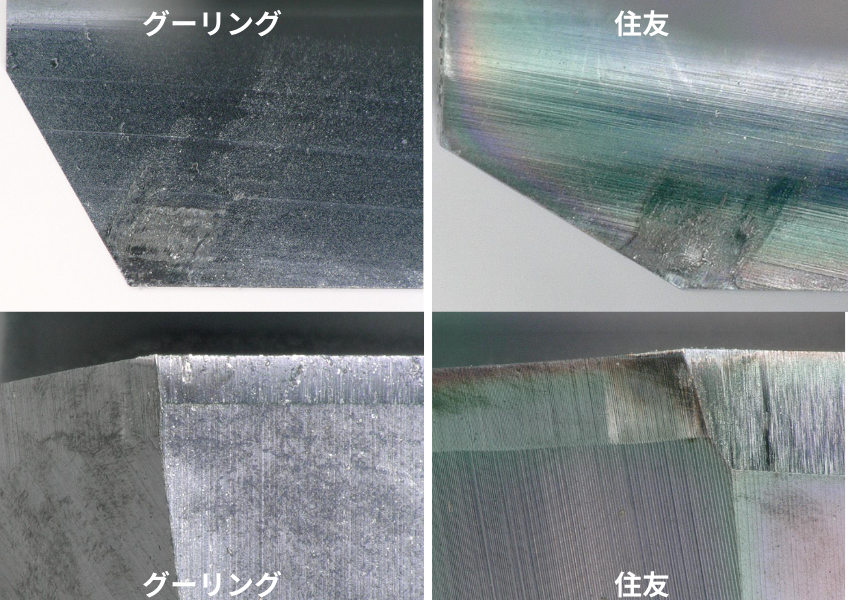

Edge comparison: After 255 holes (5.1m) processed under low speed, Vc80, f=0.6mm/rev

The appearance of Guhring HR500 did not change significantly even when it was processed below the lower limit of the recommended conditions, but Sumitomo SSR was welded even within the recommended condirions.

Edge comparison: After 255 holes (5.1m) processed under high speed, Vc250, f=1.5mm/rev

There is no wear or welding at this test condition due to higher feed and fewer scratching compared to low speed machining conditions.

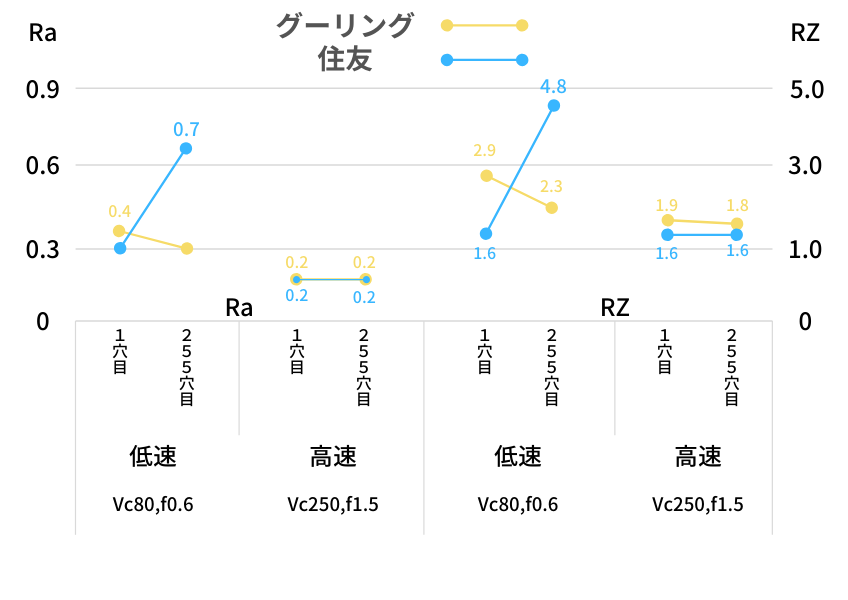

Comparison of surface roughness, roundness, cylindricity, and hole diameter change

Comparison of surface roughness

In the low speed condition, Sumitomo's deterioration is remarkable in both Ra and RZ. It is considered that is caused by welding.

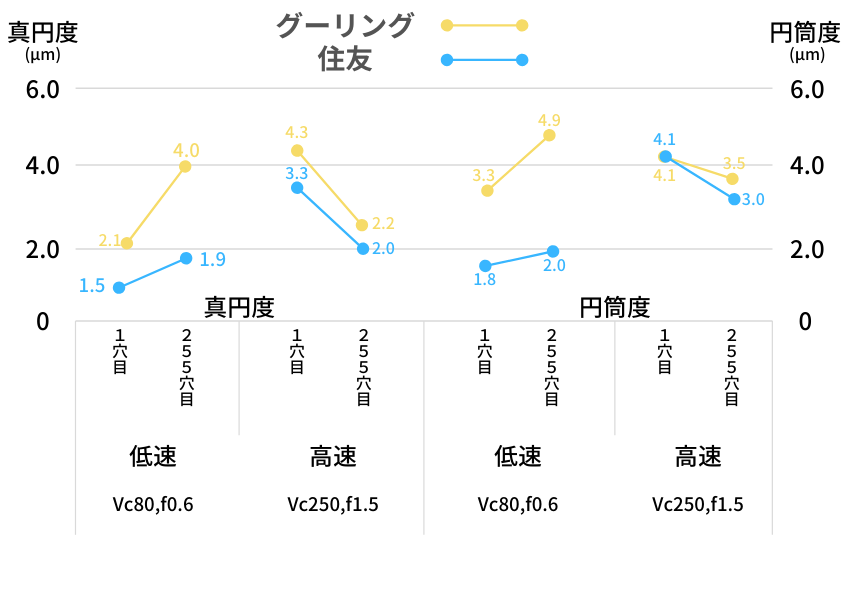

Comparison of roundness and cylindricity

Both tools are 10 μm or less and are still in high quality. Sumitomo SSR reamer tends to be slightly better at low speed.

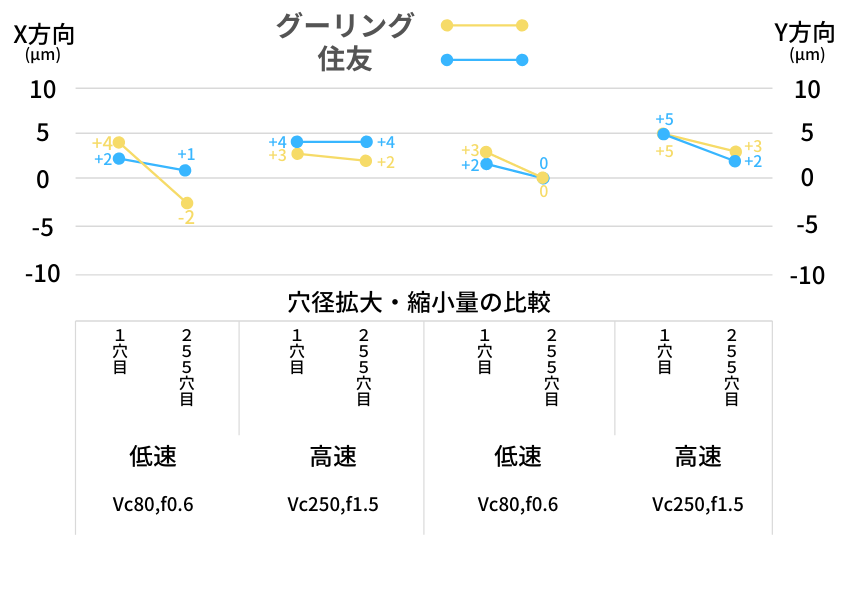

Comparison of hole diameter change

There is no big difference but Sumitomo SSR reamer tends to be slightly better at low speed.

(A graph showing how much the hole diameter has expanded or contracted compared to the actual tool edge diameter. The runout accuracy is 1 to 2 μm.)

Test result summary and explanation video

Sumitomo SSR seemed to be designed with more emphasis on sharpness than Guhring.However, welding occurred and caused poor surface roughness at the low speed of the BT30 whose is considered to be superior in terms of tool characteristics.

We interviewed about this with SSR developer.

We also interviewed the person in charge of Guhring about the chip winding of the HR500 reamer under low speed condition.

The surface roughness and hole accuracy are stable under the condition of the upper limit value rather than the lower limit value of the catalog recommended conditions by comparing and verifying under extreme machining conditions, even with BT30 with high efficiency reamers.

However, we recommend trying near the median condition, not the lower or upper limit of the recommended catalog value when using it for the first time, considering vibration and damage to the cutting edge when biting.

Research for recommended tools and cutting conditions in a high-efficiency reamer.