How are countersinks different by manufacturers?

Comparing countersink by different manufacturer.

Chamfering is very deep.

Outline

The counter sink can be easily reworked by hand or used on a machining center by carbide material.Recently, the requirements on the appearance and dimensions of the chamfered part have become stricter, and countersinks are introduced as new products from various manufacturers.

Therefore, we tried to verify the differences between each manufacturer for each work material.

INDEX

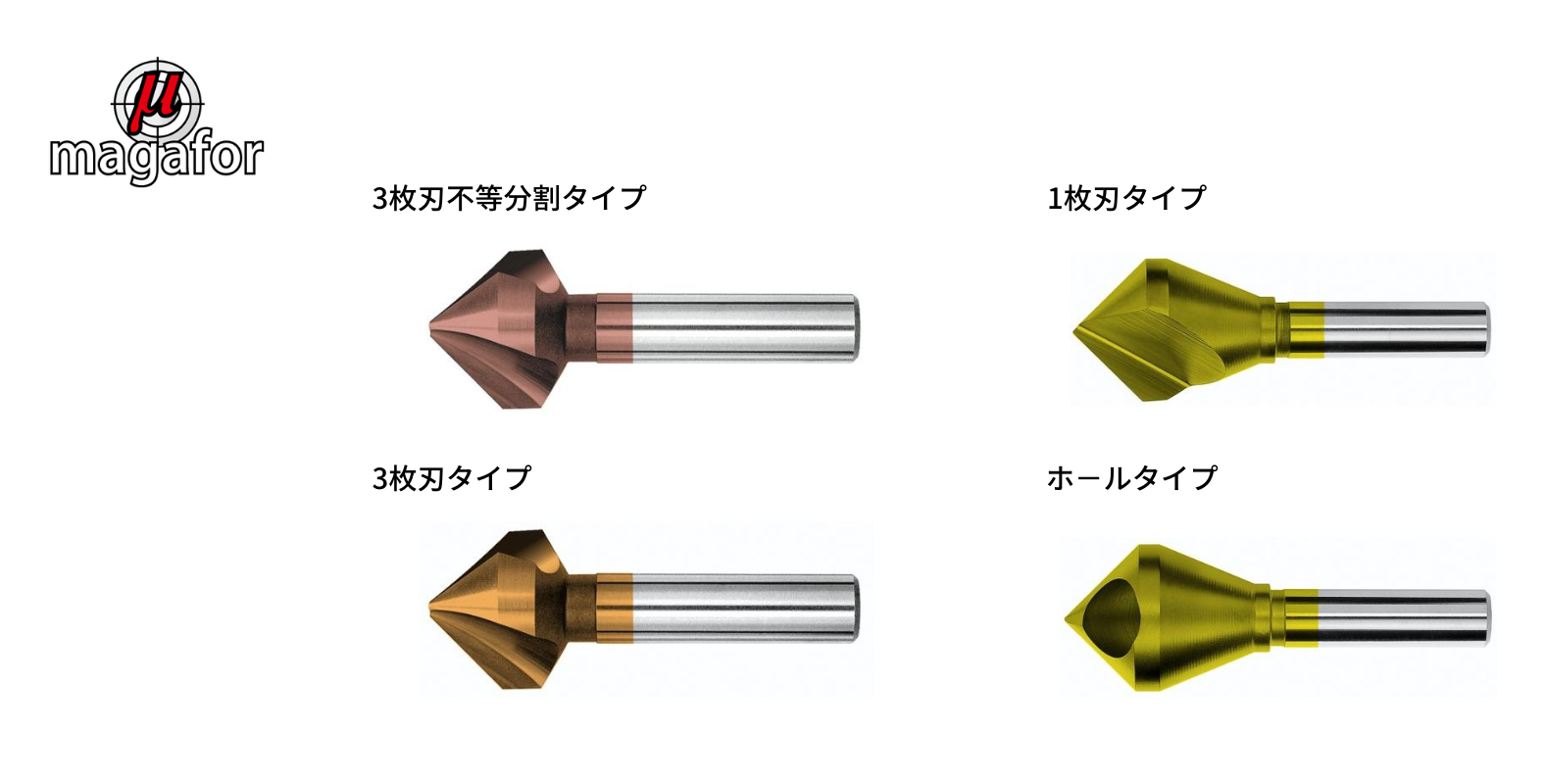

magafor: wide lineup and competitive price

Wide line up for HSS, carbide, number of flute, and sizes with competitive price.

Guhring: Spyro Tec technology

Due to convex different radii of the cutting edges with variable helical pitch provide a stable and low-vibration countersinking process

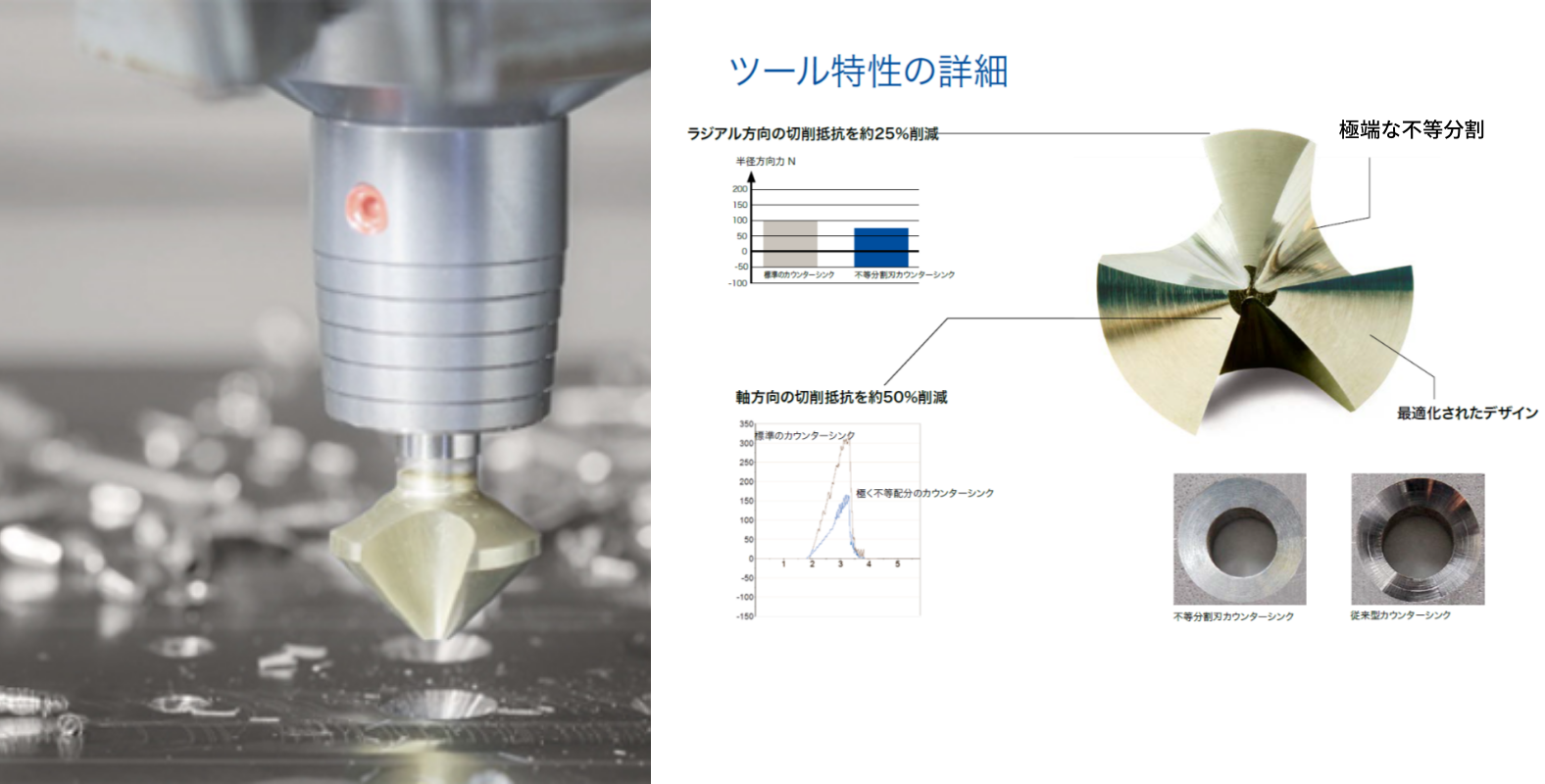

Mapal: Unique variable pitch

Cutting force is reduced by extremely unequal pitch.

Comparing test and test report

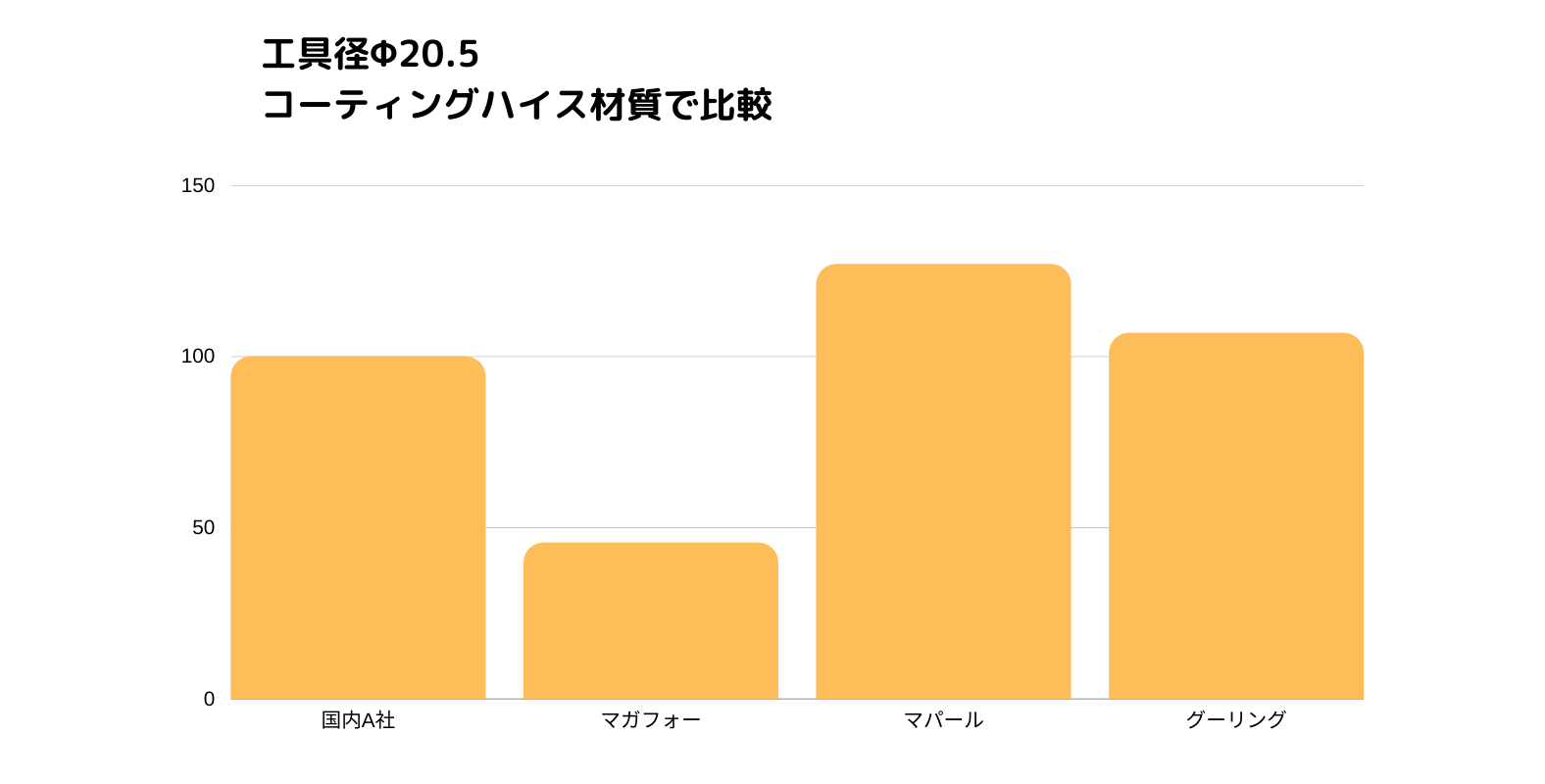

Testing with Φ20.5, 90° type coated HSS.

Comparing rough hole Φ12.

Machining with a handy type chamfering machine of about 500 rpm.

-

Machine

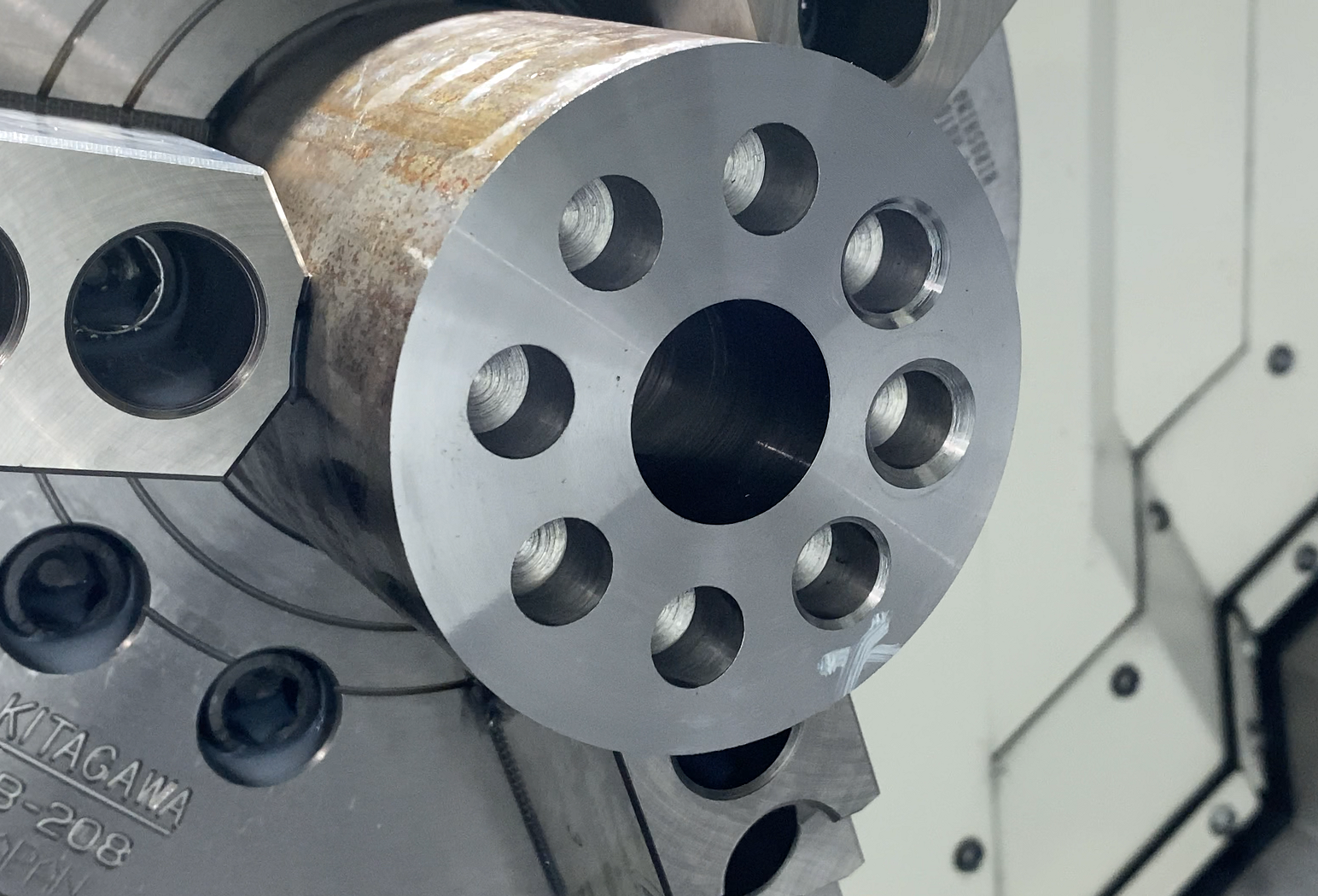

Mazak QT-compact200MYCutting condition:500rev/min、f=1mm/rev。

-

Workpiece rough hole Φ12

Workpiece material: S50C、SUS304、FC250

Test result

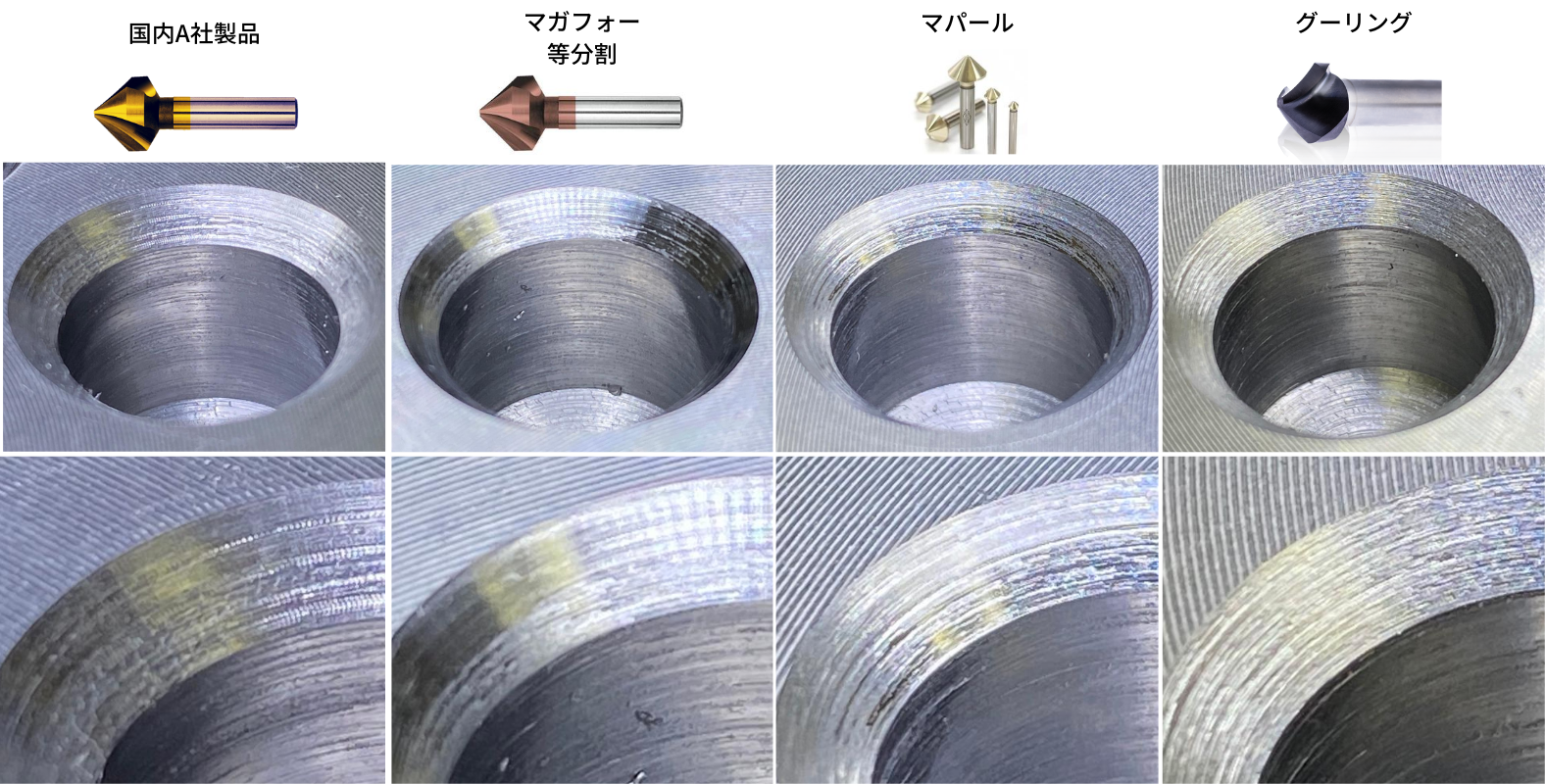

S50C

There are vibrations and burrs with product of Japanese manufacturer A. However, Guhring and Mapal products are good cutting perfomance. Especially, processed surface by Guhring product was quite smooth.

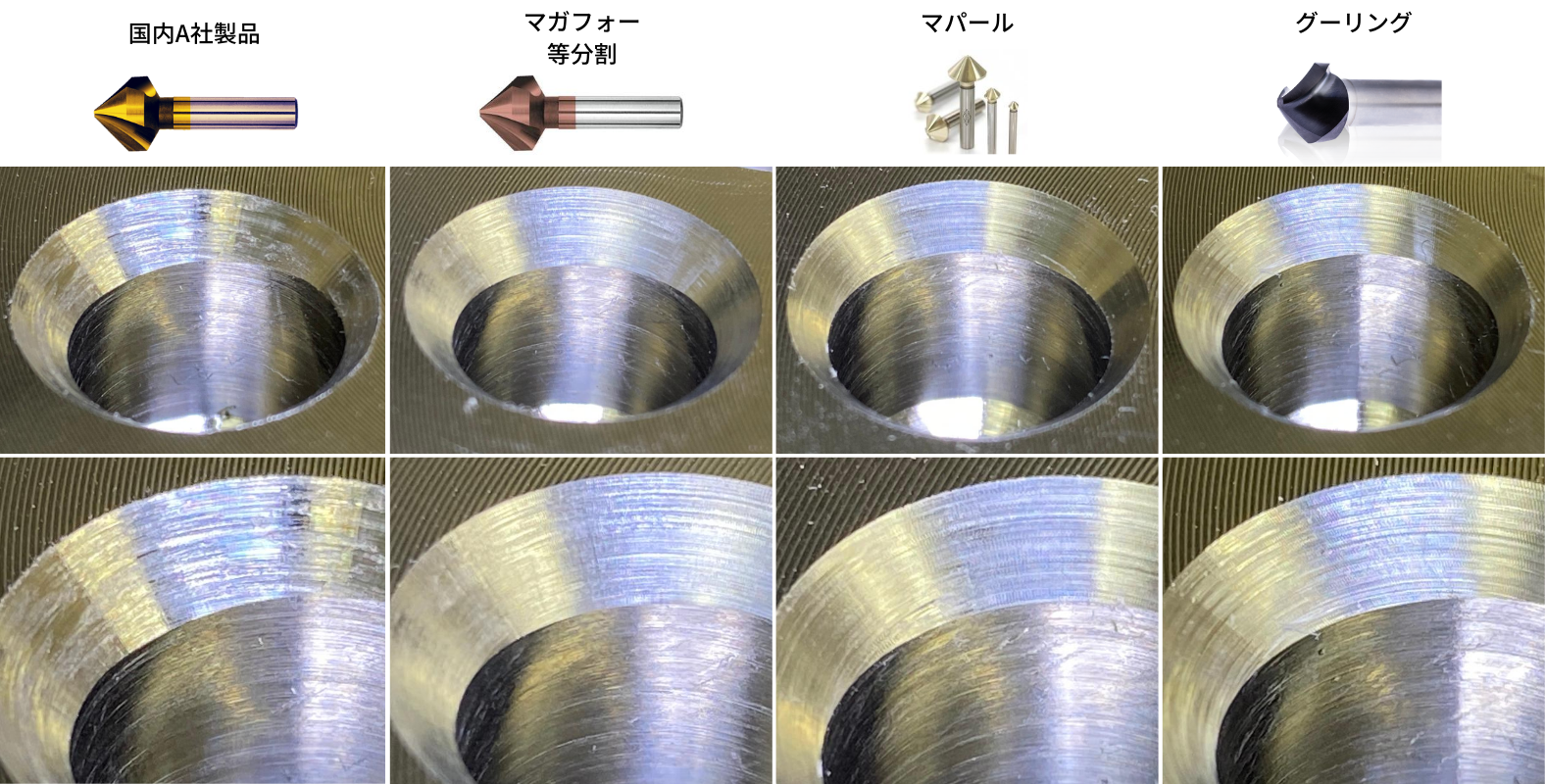

SUS304

There are galling and cloudiness by product of Japanese manufacuturer A. The other manufacturers are all good cutting performance.

FC250

There is no big difference by manufacturers, but performance by product of mapal is better a little.

Price comparison with each products